Knowledge

Rotogravure printing is a high-quality, gravure-based printing process widely used in the packaging industry. It involves engraving an image onto a cylinder, which is then coated with ink. The engraved cells on the cylinder hold the ink, while the excess ink is scraped off. The cylinder is then pressed against the substrate, transferring the ink onto the material.

Rotogravure printing offers several advantages, including excellent image reproduction, vibrant colors, and precise detail. It is commonly used for printing on flexible packaging materials such as plastic films, paper, and foil. The process is suitable for long print runs and can accommodate a wide range of substrates.

One of the key benefits of rotogravure printing is its ability to achieve consistent and high-quality results. The engraved cells on the cylinder allow for precise ink control, resulting in sharp and clear images. Additionally, rotogravure printing is capable of printing fine details, gradients, and special effects.

However, rotogravure printing requires specialized equipment and expertise, making it more suitable for large-scale production. The process involves multiple steps, including cylinder preparation, ink mixing, and color registration. It also requires regular maintenance to ensure optimal performance.

Overall, rotogravure printing is a popular choice for packaging materials due to its ability to produce eye-catching designs and durable prints. Its exceptional print quality and versatility make it a preferred option for many packaging manufacturers.

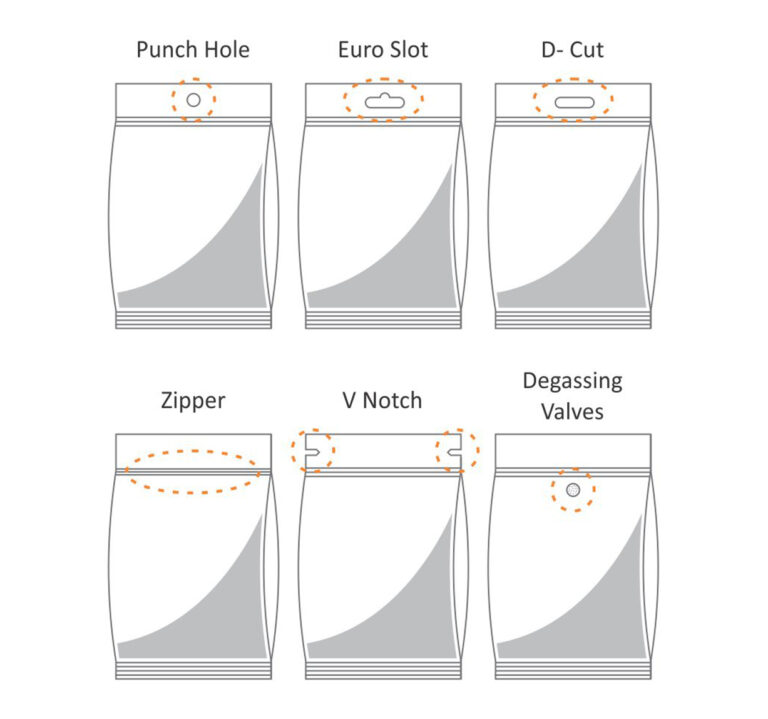

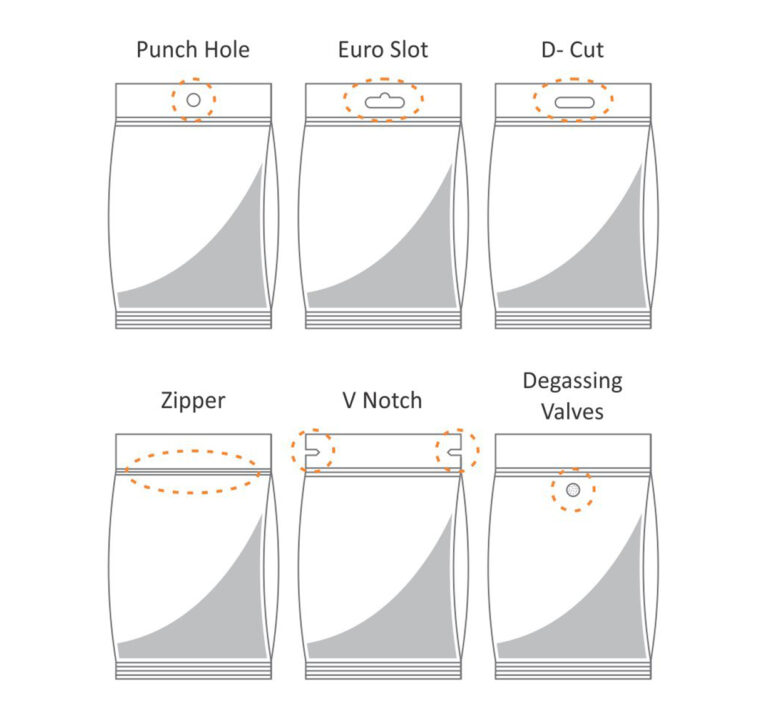

Now when you are all set to come up with your own product in the market, it’s imperative for you to know your packaging well. Packaging is the first thing that your customer will notice, so make sure to select the best Pouch for your product. So to help you to decide which Pouch will be a great choice for your pouch, we share our knowledge with you.